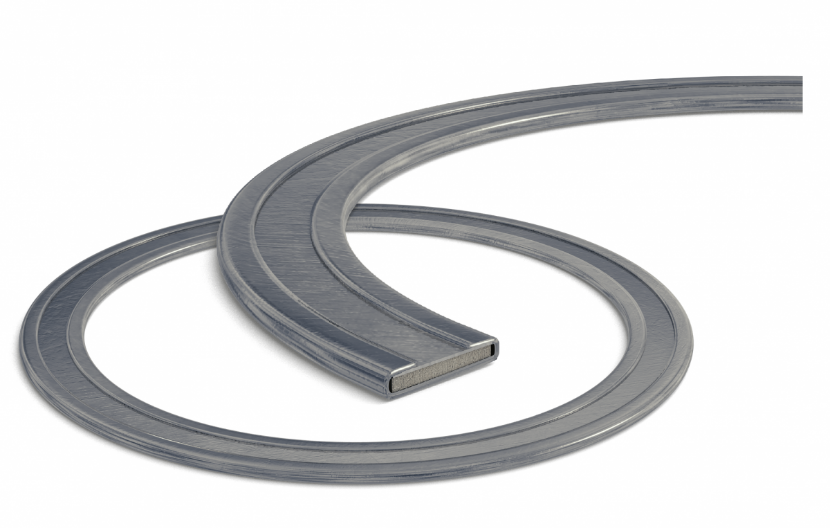

Metal

jacketed gasket

Our metal jacketed gaskets (MJG) take expanded graphite, non-asbestos or

ceramic fibers etc as the filler material, and thin stainless steel foil,

carbon steel foil or copper foil etc as the covering metal jacket. This kind of

structure effectively protects the filler against pressure conditions,

fluctuating temperatures and corrosion, providing outstanding resilience and

efficient sealing.

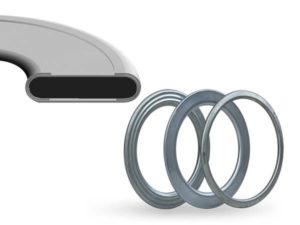

Single jacketed gasket

Single Jacketed Gasket has one of its contact surfaces covered and is ideally suited for comparatively narrow flange widths in circular and non-circular configurations. Suited for low pressure applications such as boilers, compressors, pumps, and diesel and gasoline engines, but not recommended for standard pipe flanges.

Double

jacketed gasket

The filler material is completely enclosed by a two piece metal jacket, which

covers both the inside and outside diameters and both contact surfaces. It is

designed for high pressure and temperature applications.

Flat double jacketed gasket

The metal jacket is made in plain surfaces.

Corrugated double jacketed gasket

The metal jacket is formed from a corrugated jacket providing better resilience than the metal Jacketed Gaskets, since the corrugations form multi-seals across the flange sealing face.

Metallic

Jacket Material:

CS, Soft Iron, SS304, SS304L, SS316, SS316L, Copper, Aluminum, Monel 400, etc.

Non-metallic

Filler Material:

Flexible graphite, asbestos, non-asbestos, PTFE, ceramic fiber, etc.

| Jacketing material | Maximum Temperature | Pressure |

| Carbon steel | 300°C | 20~60bar |

| Copper | 400°C | 20~60bar |

| Stainless steel (SS304, SS316, etc) | 530°C | 20~60bar |

Outer diameter: up to 5000mm.

Thickness: from 2mm to 8mm.

Sizes according to standards ASME B16.20, EN 1514-4