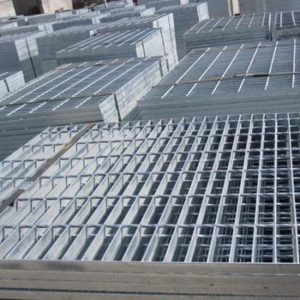

PRODUCT DETAILS

Steel Bar Gratings are manufactured with the world’s first-class computer-controlled pressure resistance welding

Email-us : info@tawajodindustrial.ae

electro-forging the twisted square-steel into flat steel. Steel Bar Gratings are classified into three styles, namely plain

style, serrated and I style as per the upper edges of bearing bars. Flat steel grating is one of the most popular steel

grating. More than 200 varieties are available based on specifications and spacing of bearing bars, and that of cross Rod

Different protective treatment can be made on the surface as environment varies.

| Bearing Bar | 25×3, 25×4, 25×4.5, 25×5, 30×3, 30×4, 30×4.5, 30×5, 32×5, 40×5, 50×5, 65×5, 75×6, 75×10,100×10 ; US standard: 1’x3/16′, 1 1/4’x3/16′, 1 1/2’x3/16′,1’x1/4′, 1 1/4’x1/4′, 1 1/2’x1/4′, 1’x1/8′, 1 1/4’x1 1/2’x1/8′ etc. |

| Bearing Bar Pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3, 32.5, 34.3, 35, 38.1, 40, 41.25, 60, 80mm etc US standard 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc. |

| Twisted Cross Bar Pitch | 38.1, 50, 60, 76, 80, 100, 101.6, 120mm, 2′ & 4′ etc |

| Material Grade | ASTM A36, A1011, A569, Q235, S275JR, SS304, Mild steel & Low carbon steel, etc |

| Surface Treatment | Black, self-color, hot dip galvanized, painted, spray coating |

| Grating Style | Plain / Smooth surface |

| Standard |

China: YB/T 4001.1-2007 USA: ANSI/NAAMM(MBG531-88), UK: BS4592-1987, Australia: AS16 Japan:JIS |

| Application | -Rotation ways, channels, and platforms for pump rooms and engine rooms in various ships;-Flooring in various bridges such as railway bridge sidewalks, over-bridges across the street;-Platforms for oil Extraction sites, car washing sites and air towers;-Fencings for car-parks, buildings and roads; drainage trench Covers and drainage pit covers for high strength . |